How Vefa Group is Revolutionizing Construction with Robotics and Smart Building Materials

What if buildings could construct themselves? How can robotics and smart materials redefine the future of construction? These are the questions Vefa Group is answering with its groundbreaking approach to modern construction. By integrating robotics and intelligent building materials, Vefa Group is setting new standards for efficiency, sustainability, and innovation in the industry.

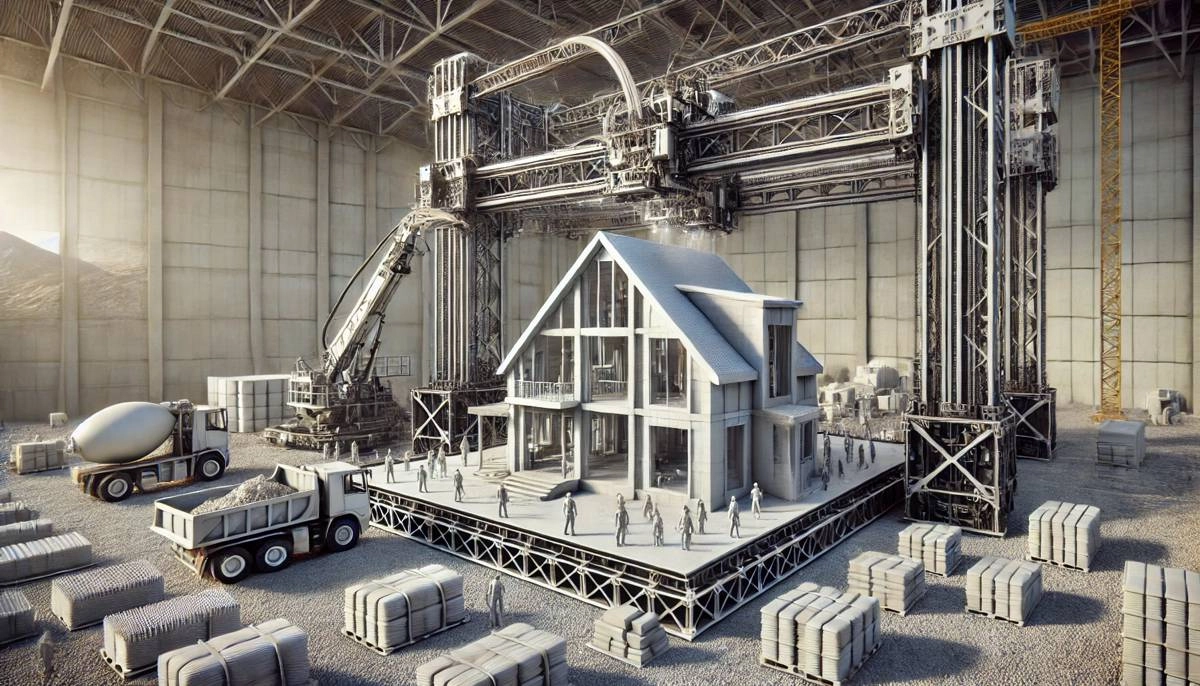

The Rise of Robotic Construction

Robotic construction is no longer a futuristic concept—it's happening now. Vefa Group has embraced this technology to streamline building processes, reduce labor costs, and enhance precision. Unlike traditional methods, robotic systems can work around the clock, minimizing human error and accelerating project timelines.

For example, Vefa Group employs robotic arms for tasks like bricklaying and welding, which are traditionally labor-intensive. These robots can complete work in a fraction of the time while maintaining impeccable accuracy. A practical application of this is seen in their recent residential project, where robotic bricklayers reduced construction time by 40%.

Smart Building Materials: The Future of Durability

Smart building materials are another cornerstone of Vefa Group's strategy. These materials are designed to adapt to environmental conditions, improve energy efficiency, and extend the lifespan of structures. From self-healing concrete to temperature-regulating insulation, the possibilities are endless.

One standout example is Vefa Group's use of photovoltaic glass, which not only provides transparency but also generates solar energy. This innovation was implemented in a commercial complex in Istanbul, reducing energy costs by 30% annually.

Sustainability at the Core

Vefa Group is committed to sustainable construction practices. By leveraging robotics and smart materials, they significantly reduce waste and carbon footprints. Automated systems ensure precise material usage, minimizing excess, while smart materials often incorporate recycled components.

A notable case is their eco-friendly housing project, where robotic production cut material waste by 25%, and smart insulation reduced heating demands by 20%. This not only benefits the environment but also lowers long-term costs for homeowners.

Challenges and Solutions

While the benefits are clear, integrating robotics and smart materials isn't without challenges. High initial costs and the need for skilled technicians can be barriers. However, Vefa Group addresses these by offering training programs and demonstrating long-term ROI through case studies.

For instance, their investment in robotic training centers has created a skilled workforce capable of operating and maintaining advanced machinery, ensuring smooth project execution.

The Future of Construction with Vefa Group

Vefa Group's vision extends beyond current innovations. They are researching AI-driven construction systems and even more advanced materials, such as carbon-negative concrete. The goal is to make construction faster, greener, and more cost-effective.

Imagine a world where buildings adapt to weather changes or repair themselves—Vefa Group is turning these ideas into reality. Their upcoming projects promise to push the boundaries of what's possible in construction.

Conclusion

Vefa Group is leading a construction revolution with robotics and smart building materials. By embracing these technologies, they are not only improving efficiency and sustainability but also setting a benchmark for the industry. The future of construction is here, and it's smarter than ever.